|

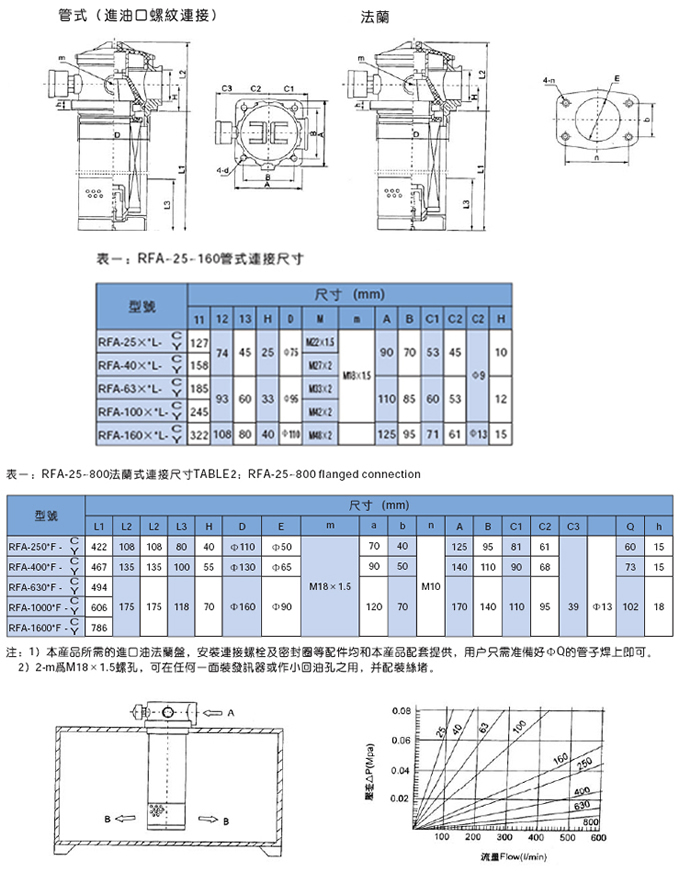

1、Connection to facilitate installation, simplifying the system piping: The filter mounted directly on the tank cover, filters, filter heads exposed in the fuel tank, the oil return tube immersed in the fuel tank. Inlet with tube and flange-type connection, thus simplifying the system piping, the system layout is more compact and easier to install the connection.

2、Set filter pollution, the sender device, asphalt bypass valve to improve the reliability of hydraulic system: When the filter is blocked or the system liquid pollutants, low temperature, pulse, etc., causing flow into the oil pressure is 0.35MPa, the sender device signal will be given instructions. Should be the timely replacement of oil filter or raise the temperature. So when you can not immediately shut down to deal with these failures, in the filter bypass valve automatically opens the lower part of the work (by-pass valve opening pressure of 0.4MPa), to ensure that filters and hydraulic systems work properly.

3、Design uses a straight back to oil filtering, so that the replacement filter or to the fuel tank is very easy: simply unscrew filter filter cover (clean cover) can replace the filter or to the fuel tank, and the filter head high with two M18 * 1.5 Oil mouth, can be either the sender or the installation of the system to return a small amount of oil tank filtration purposes.

4、With a flow diffuser: the proliferation of browser settings back to the bottom of the oil cylinder, enabling the smooth flow of the medium back to the oil tank and difficult to generate bubbles, thereby reducing the air to re-enter, and reduced deposition of pollutants have been uproar.

5、Filter glass fibrous filter material: high accuracy with a filter, through the capacity, the original pressure loss is small, the advantages of large quantity of pollutants. The filter with an absolute filtration accuracy of calibration of precision in line with ISO standards.

|

Remarks:

Remarks: